The continuity and economy of mining production depend heavily on the compatibility of three core links: crushing, screening, and conveying. As a professional manufacturer of mining equipment, we focus on the R&D and production of conveyor belts, idlers, crushers, and screening equipment. Below is an analysis of the core value and application logic of mining equipment from technical principles, material applications, industry trends, and selection & maintenance perspectives.

Crushing is the first process in mining production, which overcomes the internal cohesion of ore through external force to convert large materials into processable small particles.

- Jaw Crusher: Adopts the extrusion and occlusion design of movable jaw and fixed jaw, suitable for primary crushing of materials with hardness ≤300MPa such as granite and iron ore. It can crush 1-meter-level large ore into tens of centimeters.

- Cone Crusher: Based on the laminating crushing principle, realizes medium and fine crushing through the eccentric swing of the inner cone. It produces uniform particle size and is suitable for secondary crushing of high-hardness ore.

- Impact Crusher: Uses the impact energy generated by the high-speed rotor driving the hammer to achieve “stone-on-stone” crushing. With a crushing ratio of up to 50 and excellent particle shape, it is suitable for refining medium-hard materials such as limestone.

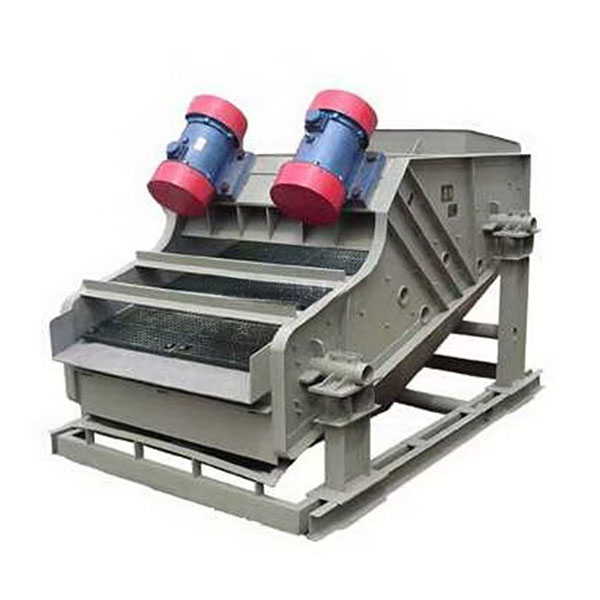

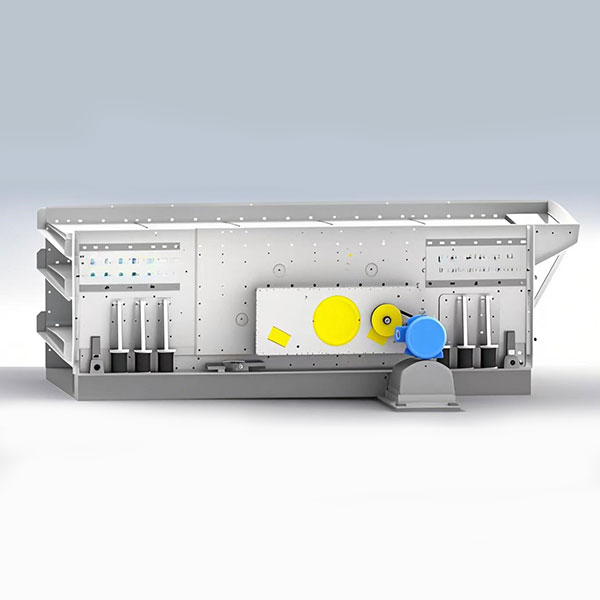

Screening equipment is responsible for separating materials of different particle sizes and providing raw materials that meet requirements for subsequent processes. It is mainly divided into two types:

- Vibrating Screen: Uses a vibration motor as the excitation source to make the screen box produce periodic vibration. Materials are classified on the screen surface, and particles smaller than the screen hole are discharged through the screen. It is suitable for post-crushing classification, tailings dry discharge and other scenarios.

- Spiral Classifier: Separates coarse and fine particles by gravity sedimentation. Coarse particles sink to the bottom of the tank and are transported back to the grinding equipment by the spiral blade, while fine particles overflow with the slurry. It is often combined with a ball mill to form a closed-circuit system.

Conveying equipment connects various production links to ensure continuous material transportation, mainly composed of conveyor belts and idlers:

- Conveyor Belt: As the core component for material bearing and transportation, it needs to meet the requirements of long-distance and large-inclination (≤18°) transportation. Different performance types such as wear-resistant, corrosion-resistant, and flame-retardant can be selected according to material characteristics.

- Idler: Plays a key role in supporting the conveyor belt and reducing operating resistance. Stable operation of the conveyor belt is guaranteed through reasonable layout, reducing friction loss and energy consumption.

- Wear parts of crushers (jaw plates, hammers) are made of high chromium cast iron or high-quality alloy steel, with hardness up to HRC55-65. The wear resistance is significantly improved, extending the service life.

- The surface of the conveyor belt is made of high wear-resistant rubber material, enhancing tear resistance and wear resistance, suitable for long-term use under complex mining conditions.

- Idlers are made of ultra-high molecular weight polyethylene or wear-resistant rubber material, whose wear resistance is 5-7 times that of ordinary metals, while reducing the friction coefficient with the conveyor belt.

- Idlers adopt a triple sealing design, with a polyurethane dust cover on the outside and high-temperature grease filled in the bearing cavity, enabling 3-year maintenance-free operation in humid and dusty environments.

- Crushers adopt a hydraulic adjustment system, which can quickly adjust the discharge port size to meet different particle size requirements and improve production flexibility.

- The screen angle and vibration frequency of screening equipment are optimized to increase processing capacity and screening efficiency, reducing material blockage.

The global intelligent mining market continues to grow. Real-time monitoring of equipment status (such as dynamic tracking of vibration, temperature and other parameters) is realized through IoT and sensors, facilitating predictive maintenance and reducing downtime.

- Equipment is integrated with intelligent control systems to achieve automatic start-stop and load regulation, improving production efficiency while reducing labor costs.

- Data management runs through the entire production process, optimizing equipment operating parameters through data analysis to achieve a balance between production capacity and energy consumption.

- Equipment design complies with environmental standards. Crushers are equipped with dust collection systems, and conveyor belts are made of low-noise materials to reduce dust and noise pollution during production.

- Energy-saving technologies are widely applied. By optimizing equipment structure and adopting high-efficiency motors, energy consumption per unit output is reduced, practicing the concept of sustainable development.

- Crusher Selection: Determine the model according to ore hardness (cone crusher for high hardness, impact crusher for medium hardness), production capacity requirements and discharge particle size requirements.

- Screening Equipment Selection: Select screen hole size, vibration frequency and equipment material according to material particle size and processing capacity. Stainless steel or engineering plastic materials can be used for corrosive materials.

- Conveyor Belt and Idler Selection: Select the appropriate type according to transportation distance, inclination angle and material characteristics (temperature, humidity, corrosion). The bearing capacity of idlers needs to be strengthened for heavy-load scenarios.

- Regularly check the wear of crusher wear parts, replace jaw plates and hammers in a timely manner to avoid production impact due to component damage.

- Regularly clean dust on the surface of idlers, check sealing performance and rotation flexibility, and test concentricity every quarter to prevent conveyor belt deviation.

- Conveyor belts should avoid contact with sharp objects, adjust tension regularly, and repair surface damage in a timely manner to extend service life.

The performance of mining equipment directly affects production efficiency and operating costs. As a professional manufacturer of conveyor belts, idlers, crushers, and screening equipment, we always take industry needs as the guide, providing customized equipment solutions suitable for different working conditions through material upgrading, structural optimization and process innovation. Whether it is a high-wear crusher, precision screening equipment, or an efficient and energy-saving combination of conveyor belts and idlers, all have undergone rigorous testing and meet industrial-grade standards.

For customized equipment solutions or technical consulting, please feel free to contact our professional team for full-process technical support and services.